Isifudumezi seCeramic band

Inzuzo ephambili yeeyunithi zesifudumezi se-ceramic kukuba ziyakwazi ukufudumala ngoko nangoko kwaye kuthatha ixesha elincinci kakhulu ukuba uzive iziphumo zokufudumeza kolu hlobo lwesifudumezi.Olu yilo lubenza babe zezona zifudumezi zombane ezisebenzayo ezikhoyo.

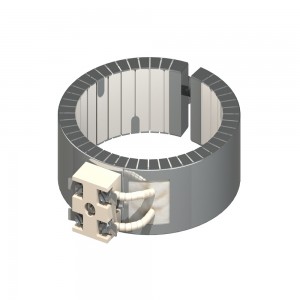

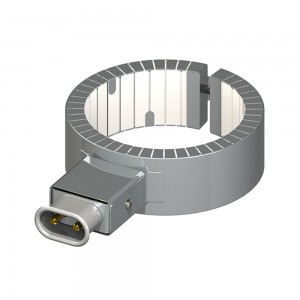

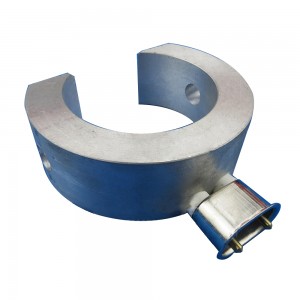

Ukusetyenziswa okuqhelekileyo kukubumba iplastiki, i-extrusion kunye ne-molding presses.Izifudumezi ze-Ceramic band nazo zisetyenziselwa ukufudumeza umbhobho, ukunyangwa kobushushu kunye ne-autoclaves okanye nayiphi na isicelo apho kukho imfuneko yokubeka ukushisa kwi-cylindrical surface.

1.Uyifektri?

Ewe, siyifektri, bonke abathengi bamkelekile ukuba bandwendwele umzi-mveliso wethu.

2.Ziziphi iziqinisekiso zemveliso ezikhoyo?

Sinezatifikethi ezinje: ATEX, CE, CNEX.IS014001, OHSAS18001,SIRA, DCI.njl

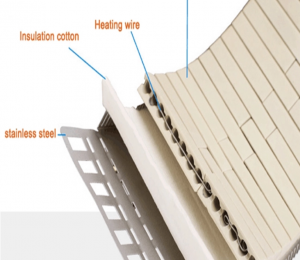

3.Yintoni ekhethekileyo malunga nesifudumezi seceramic?

Izifudumezi zeCeramic zisebenza ngombane, nto leyo eyenza ukuba zingantsonkothanga kakhulu kunezo zisebenza ngeoyile.Into yokufudumeza ngeceramic iphinda ifudumale ngokukhawuleza, ifuna amandla amancinci ukuze ifudumale.

4.Ziba shushu kangakanani izifudumezi zeceramic?

Ezi mpawu zivumela izifudumezi ze-ceramic zivelise ukuya kuthi ga kwi-1,000 W/in.2 kwaye isebenze ukuya kuthi ga kwi-600 ° C (1,112 ° F) ngokuxhomekeke kuyilo lwe-heater kunye neeparitha zenkqubo.(Obona bukhulu kunye nobuncinci boxinzelelo lwamandla bunokwahluka ngombane, indawo engaphezulu, kunye neeparamitha zosetyenziso.)

5.Ingaba izifudumezi zeceramic zisebenzisa umbane omninzi?

Izifudumezi zeCeramic zisebenza kakuhle kwaye zisebenza kumbane.Oku kuthetha ukuba akukho ngozi yokukhutshwa kwetyhefu efana nekhabhon monokside kwindawo ekufutshane.Xa zisebenza kakuhle, izifudumezi zeceramic zikwasebenzisa izixa ezisezantsi zombane kunezinye izifudumezi zasemoyeni